Testing & Standards

Peel Adhesion

The peel adhesion test is used to measure the ability of the adhesive to stick to a variety of substrates including stainless steel, glass, high-density polyethylene (HDPE), low-density polyethylene (LDPE), polystyrene, polypropylene (PP), and polyvinyl chloride (PVC), and corrugated cardboard.

The peel adhesion test is used to measure the ability of the adhesive to stick to a variety of substrates including stainless steel, glass, high-density polyethylene (HDPE), low-density polyethylene (LDPE), polystyrene, polypropylene (PP), and polyvinyl chloride (PVC), and corrugated cardboard.

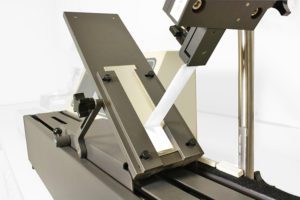

This test is carried out using an Adhesion/Release Tester. After the substrate has been cleaned and dried, a 1”x6” sample of the material is adhered to it using a five-pound hand roller. Immediately after, 25mm of the material is peeled off of the panel and clamped to the movable jaw of the instrument so that it maintains a 90o peeling angle during the peeling of the next 75 mm at a constant speed. As it peels back the material, the device measures the force required to effect peel. This gives us an idea of how aggressive the adhesive is and to which substrates it adheres best.

We follow ASTM International Designation D 3330/D 3330M- 04 Method F: Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape as a guideline for our peel adhesion test, but modify it to include corrugated cardboard.

catalog Download »